An up-to-date statistical analysis of major non-compliances in the automotive sector.

The automotive sector is characterised by a continuous drive for evolution and improvement. A fundamental part of this process is the identification and resolution of problems and non-conformities. In this article, we will present an up-to-date analysis of major non-conformities, based on the latest statistics provided by the International Automotive Task Force (IAFT) Global Oversight.

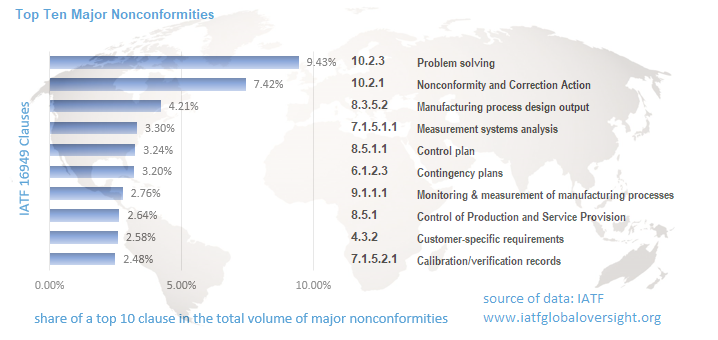

Top Ten Major Non-Compliances

- Problem Solving (9.43%) - Requirement No. 10.2.3: The biggest non-conformity concerns problem solving. Companies show difficulties in implementing effective problem-solving procedures, a crucial component in ensuring product quality and reliability.

- Non-Compliance and Corrective Actions (7.42%) - Requirement No. 10.2.1: Procedures for handling non-conformities and implementing corrective actions are another critical, often insufficiently managed area.

- Manufacturing Process Design Output (4.21%) - Requirement No. 8.3.5.2: The output of the production process design is another problematic node, with non-conformities related to the design and implementation of production processes.

- MSA (3.30%) - Requirement No. 7.1.5.1: MSA (Measurement Systems Analysis) is essential to ensure the accuracy and reliability of measurements in the production process. Non-conformities in this area can compromise product quality.

- Control Plan (3.24%) - Requirement No. 8.5.1.1Non-compliance with the Control Plan is an important area for improvement, with companies needing to refine their control and monitoring processes.

- Contingency Plan (3.20%) - Requirement No. 6.1.2.3The importance of an adequate contingency plan becomes clear, with non-compliances indicating a lack of or inadequate contingency plan.

- Monitoring and Measurement of Production Processes (2.76%) - Requirement No. 9.1.1: Effective management of production processes requires adequate monitoring and measurement, an area where many non-conformities emerge.

- Production Control (2.64%) - Requirement No. 8.5.1: Accurate management and control of production is essential to ensure product quality, but this area is often lacking.

- Customer Specific Requirements (CSR) (2.58%) - Requirement No. 4.3.2: Companies sometimes struggle to meet specific customer requirements, a factor that can affect customer satisfaction and the company's reputation.

- Calibration Verification Records (2.48%) - Requirement No. 7.1.5.2.1: Finally, the last of the top ten concerns calibration verification records, which are crucial for ensuring the reliability of measurement processes.

These statistics underline the areas where the automotive industry must focus its efforts to improve compliance and, consequently, product quality and reliability.

Insights and Continuing Education: How to Improve Compliance in the Automotive Sector

The analysis of the top ten non-conformities highlights the importance of a continuous improvement and updating process for all companies in the automotive sector. However, to effectively address these issues, training is a key element.

Why Training is Fundamental

Training helps organisations better understand industry-specific requirements, identify and manage risks, develop and implement effective control and contingency plans, and properly manage production and manufacturing processes. In addition, with proper training, companies can learn how to effectively manage non-conformities and corrective actions, design effective production process outputs, and comply with customer-specific requirements.

How Automodemy can Help

Automodemy.com is a leading portal for automotive-specific training. I training courses offered by Automodemy.com can help companies close gaps and improve their compliance.

Whether it is an intensive course on a particular requirement, such as problem solving (requirement no. 10.2.3) or the management of non-conformities and corrective actions (requirement no. 10.2.1), or a more general course on theimplementation of a quality management system in industry automobile, Automodemy.com has the right course for you.

The MSA (Measurement Systems Analysis) coursefor example, can help to better understand the importance of an accurate analysis of the measurement system to ensure the reliability of measurements in the production process. Similarly, the Control Plan course provides the necessary skills to develop and implement effective control plans.

Training is an investment that pays off in increased product quality, reduced non-conformities, increased customer satisfaction and, ultimately, the company's success in the automotive market.

Automodemy.com is here to support your company on this path. Check our courses and start your journey of continuous improvement in the automotive industry today.

0 Comments