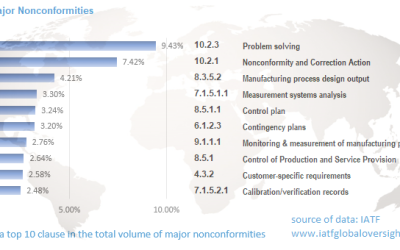

An up-to-date statistical analysis of major non-conformities in the automotive sector. The automotive sector is...

Problem Solving Articles

read more

Problem Solving - 5W Analysis

Introduction to the 5 Why and the 5 How Have you ever had a problem that kept recurring? Having to deal with a...

What is the 8D method?

The 8D method is a quality management tool that enables an inter-functional team to convey ideas for the...

Problem Solving - 5W Analysis

Introduction to the 5 Why and the 5 How Have you ever had a problem that kept recurring? Having to deal with a...

What is the 8D method?

The 8D method is a quality management tool that enables an inter-functional team to convey ideas for the...